Fixing

hardware problems is not

been easy and takes a lot of time to consume rather than software

problems, it is because when it comes to software handling you don't

really need to open or dismantle a mobile phone handset, because only

few of them really need to. In most cases like this, many among

mobile phones technician focus on software handling like especially

unlocking,

for it less time consuming and more flexible to do with. This is been

true that mobile phone technicians were separated into two specialties,

like Hardware expert and Software expert, that is what the term they called it; It because mobile phones is a combination of software and hardware mechanism.

But there are also many mobile phones masters that can manage and do both hardware and software specialty and skills. They gained this knowledge by years of experience, and not only that they also earned

much more income rather than to those staying at one particular specialty.

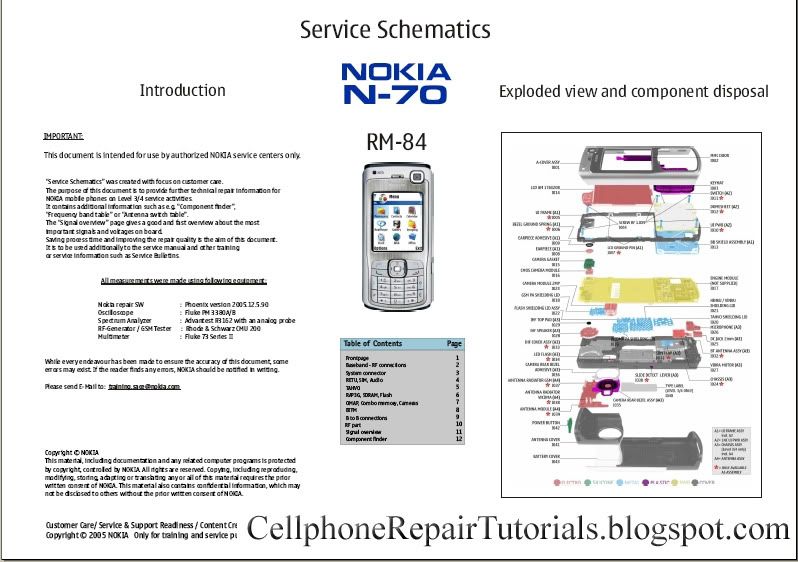

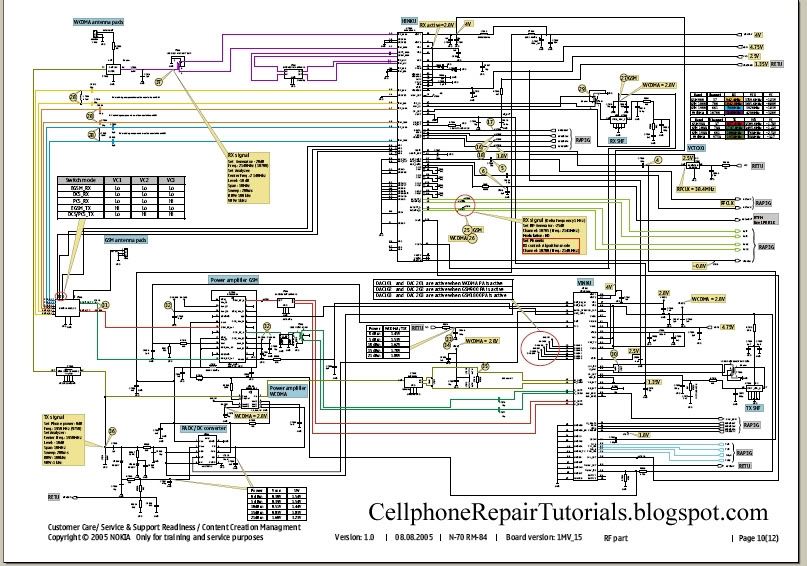

Now, here is

the basic step by step repair procedure on hardware

troubleshooting on mobile phones. Various mobile phones

have different circuits and components or parts layouts and designs.

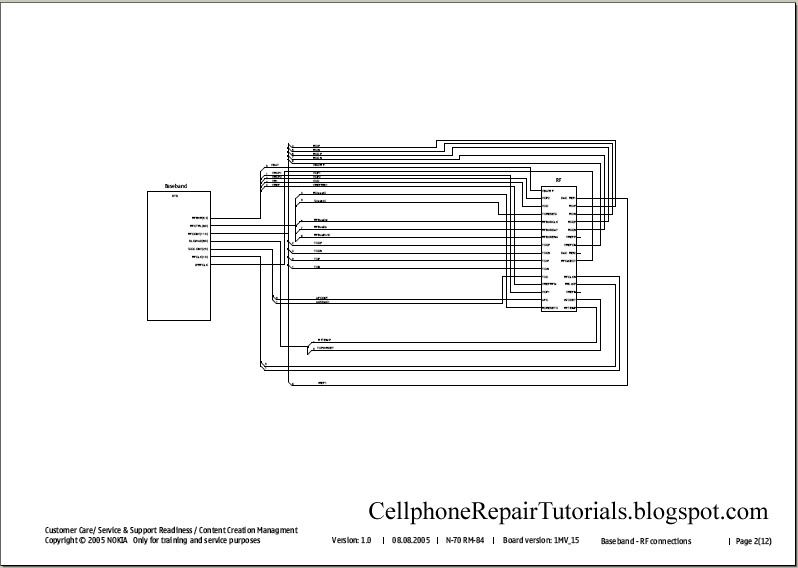

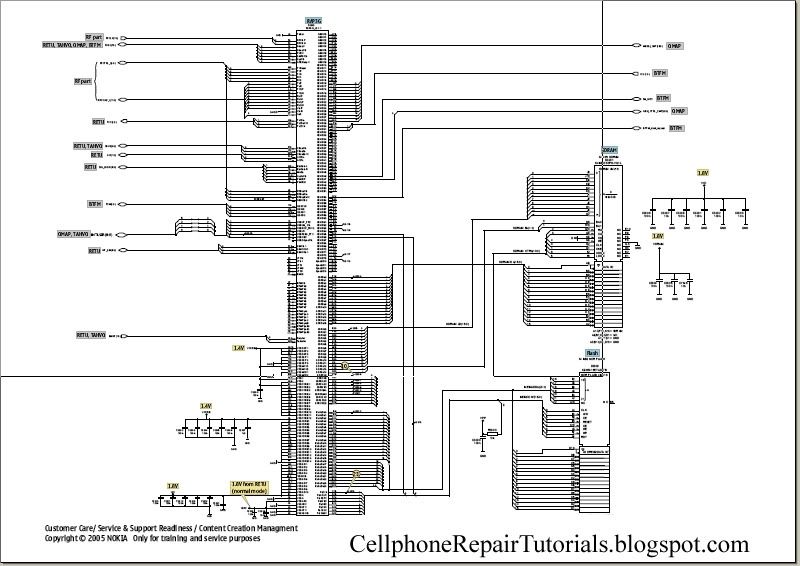

First thing you must learn and be familiar with is, how each circuit

components or parts is being mounted, connected, assembled or designed.

First step in handling troubleshooting procedure.

1.

Visualization Checkup- Before proceeding to anything always consider the fact that a mobile phones

handset is fragile object. Check and have take a look around every inch

of the handsets package and layout, In this manner you can identify if

the handset is in repairable condition, something like checking the

whole printed circuit board components and parts, if it is free from

dust,corrosion, bended,breakage etc.

2.

Know the Phones Status - Ask the the user or

the costumer about the phones history before the problem occurs. Letting

know the phones history like accidentally soaked into a liquids or

water, dropped,throwned and etc.

In this manner you can get an idea where to start or begin with.

3.

Do Software Check up - Use a certain

flashing device for that particular handset product to be able to read

logs, logs is a reading of mobile phones firmware programmed and

installed unto it. This is a big help for most advance mobile technician

this days, A logs reading can help you where the faulty line or parts

occurs. If you are not familiar about how to read logs you can ask to

that certain flashing device product supporters and creator.

You can do flash, reformat at first hand if found something wrong with the mobile phones firmware. If all methods of software already done and nothing happens, proceed to hardware troubleshooting.

4.

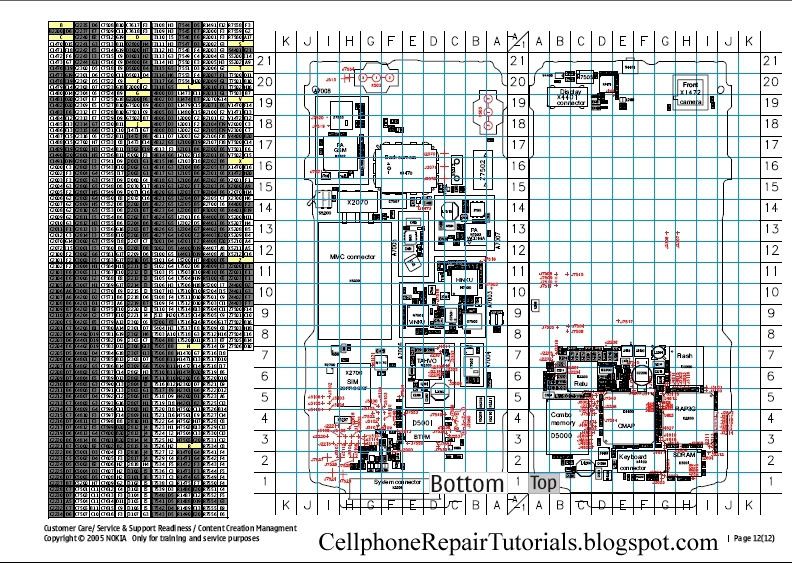

Analyze The Circuit - After dismantling and do visualization check up,be patient and take your time to analyze the whole circuits layout, and

think of a step by step plan procedure in your mind where or how to begin with. A

Special Operation Procedure

is good way and a reliable source of idea within yourself, not only by

enhancing your skills but you are also practicing a self discipline

method.

Now lets take one example of basic hardware troubleshooting methods in

one particular mobile phone handsets. In this simple way you can then

manage how to troubleshoot or been able on finding faulty parts or

components within a mobile phone circuitry.

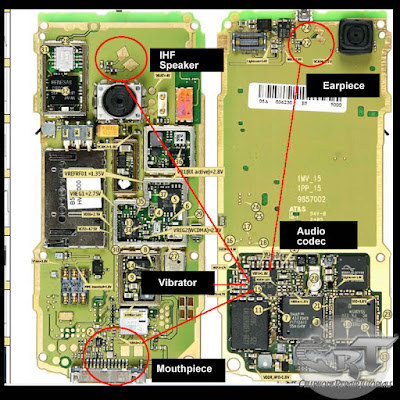

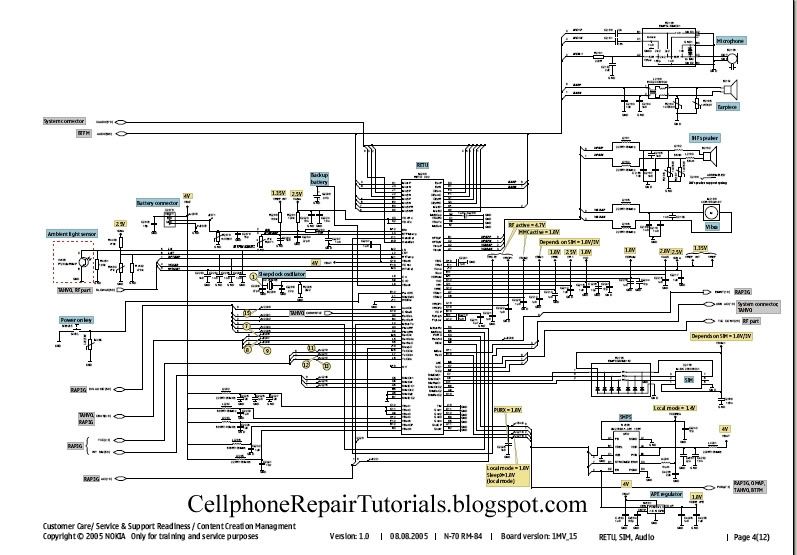

An example here is Nokia 6300, now assuming that this handset having a faulty microphone or mouthpiece.

Do the basic procedures mentioned above, assuming that you are familiar with the

Mouthpiece or microphone circuit, and already know

how to check a microphone or mouthpiece component.

you can now do this step below;

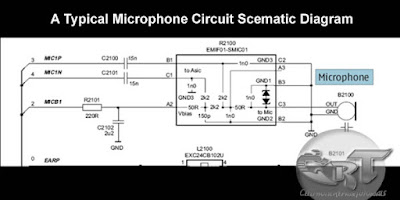

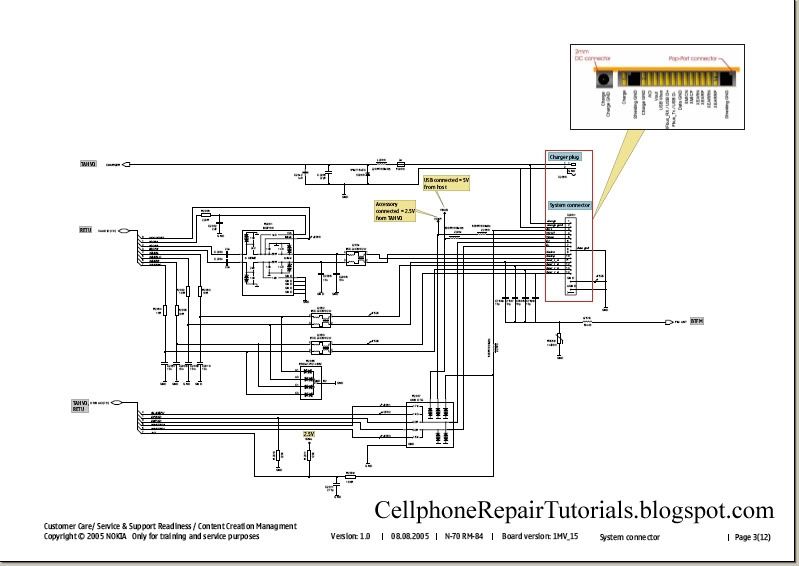

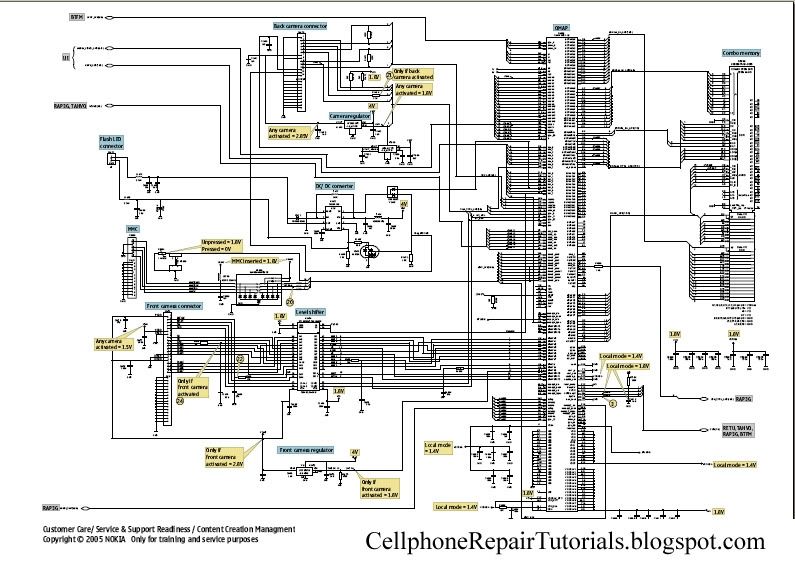

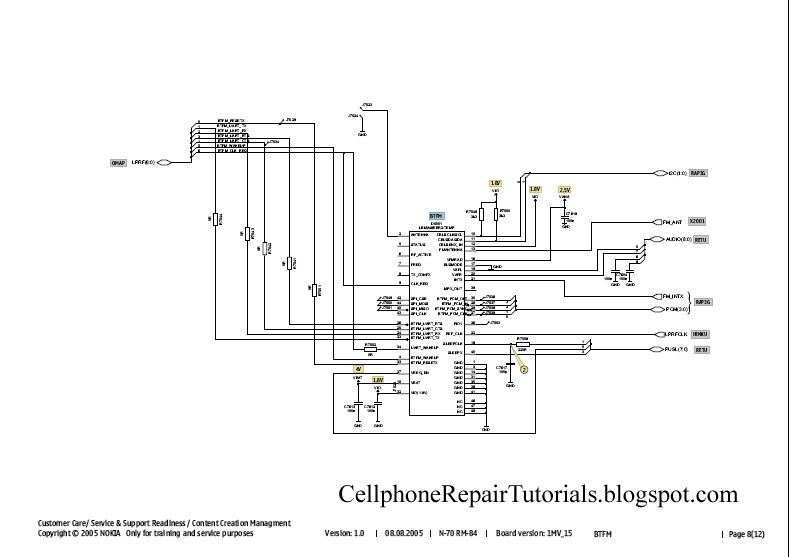

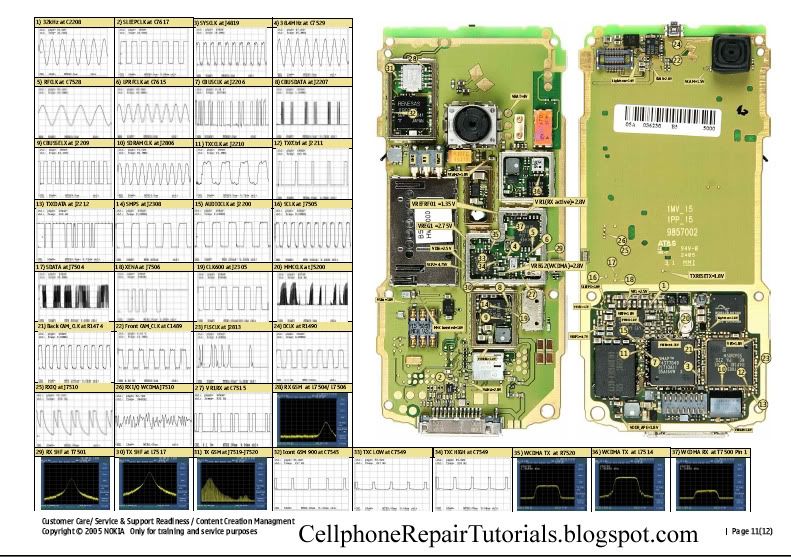

1. Find any available

schematic diagram and locate the microphone circuit layout on it. Remember where each parts and components location and do a mapping like this.

2. Use a multi-tester and check the pads for a short circuit, this is not always happen but it is also unpredictable to a mobile phones

short circuit might occurs, you are not checking the outer mounted

components but the internal lines with it. Just set the tester to x1

resistance value, I preferred analog multitester in this lesson for it

is cheaper to purchase rather than the digital. Now connect both test

probe to the inner and outer layer of the mouthpiece terminal pads, then

do it again in opposite manner, a short circuit have both readings

closer to zero ohms.

3. Trace the line paths between the first or the closest component connected to each terminal pads.

The circuit diagram shows that there are coil filter in both lines,

connect the tester across each coil terminal leds, your not just

checking the lines here but also

checking the the coil as well.

4. Now the next step is to leave behind the line paths between the coil

to the EMI-Filter for it is uncheckable beyond that paths for the EMI-

filter is an IC. you need to remove it first before you can check on

that lines , which will be done later at the last steps of procedures.

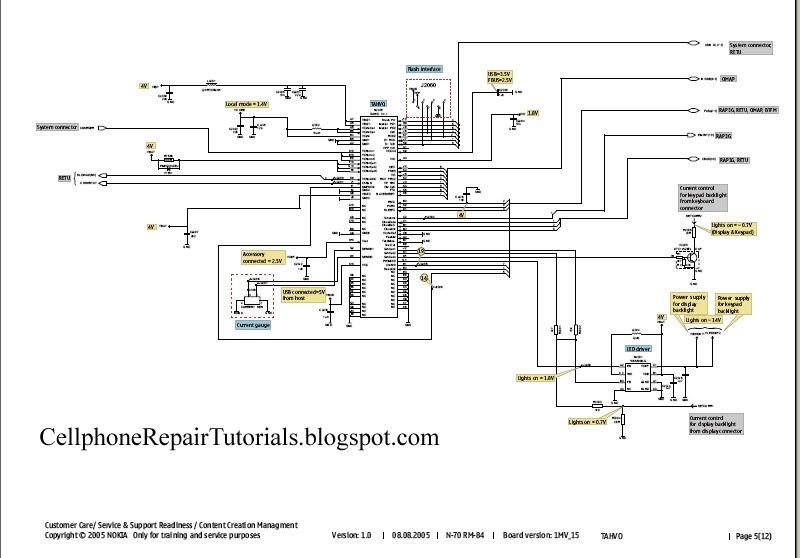

Now next to move on to the opening lines and component where

the test probe can connect with, the two filter capacitors and both coils which are an open path where you can connect the test probe on it. now connect or attach both probes at the end of each line indicated in red.

5.

Now check the remaining open path which is the Resistor, you can't

check the line paths on those area for it ends up connected to Retu IC.

So just then proceed to check its resistance value instead.

6. If all those mentioned lines above is all in good condition you may

now proceed to suspect the EMI-Fiter is having a problem or faulty. You

then now remove it from the Printed circuit board then do a line check

up from the mouthpiece terminal to that EMI-filter terminal bumps where

it is being connected.

You

can refer to the schematic diagram for each terminal specification. You

may now can check the IC itself by analyzing the internal circuitry

inside it. I advice just replace a good and working one if not so sure

about.

8.

It this step is most complicated job to do with, specially for

beginners.This is one of advance troubleshooters skills. If found all

of those line paths and components above were in good conditions. The

last part is to work a power management IC itself for the audio codec

circuit is also within that chips.

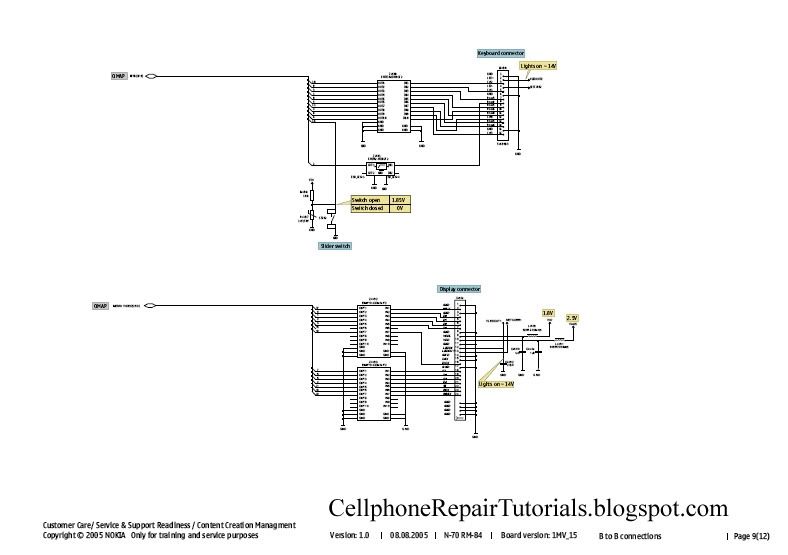

Now, if the last and final suspected parts is the chips, you must need

to rework it, Reheating it the first will do and might as well also

work. But if the problem still remain, Reworking it is the best advice

that suites out.

but also do not forget to check the line paths between the mouthpiece

circuit area, while the chips is being remove and out on the PCB layout,

it is a proper time to check the ball bumps terminal where that certain

microphone is being connected. an example of tracing the ball bumps

terminals below.

okay,

that's it for a while, for there are lots of techniques we are going to

tackle sooner, hope you do understand a little bit with this method.

Just install the

Just install the